Products

MEDSEAL® - MSIDV

Electrically driven medical impulse sealer with optimal seal integrity

Interested in our MEDSEAL® - MSIDV?

We are more than willing to support you with your request or run a demo with your packaging

Validatable impulse sealer for safe packaging of medical devices

The MEDSEAL® is suitable to safely pack medical devices and other medical products. The built-in electromagnets perform a powerful seal pressure, guaranteeing a strong seal of various medical bags (Polypropylene, Polyethylene, Paper-PP).

Your ideal seal recipe can be stored in the easy to operate digital control panel. Validation results on seal pressure, seal temperature and seal time can be processed to your PC via the integrated software and USB port.

The MEDSEAL® (MSIDV) fully complies with the DIN 58953 part 7 and ISO 11607-1 standards.

The stainless steel design is easy-to-clean providing a durable heavy duty solution. Depending on the product to be packed we offer the MEDSEAL® in two sizes: 460 mm sealing length (460 MSIDV) and 610 mm sealing length (611 MSIDV). Both models are digitally operated and validatable.

An optional knife enables to cut the excess film above the seal. This facilitates optimized hygiene and minimizes your packaging size.

To sum up:

- Validatable impulse sealer

- Electrically driven seal bars (no external air pressure needed)

- Compatible to EN868-5, section 4.3.2. and DIN 58953 part 7 and ISO 11607-1 standards.

- Heavy duty design - configurable with optional knife

- Easy-to-use digital control panel, 1 recipe

- Available in two seal bar lengths - 460 or 610 mm

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Suitable for medical applications

This packaging solution fully complies to the high requirements applied to safely pack medical products. Your product quality and safety are our highest priority.

Plug and play

The MSIDV is constructed with integrated electromagnets, which means no need of external air pressure and easy implementation of this medical sealer into your production.

Guaranteed safe packaging

The validation feature ensures that critical process variables are controlled guaranteeing a safely packed product after each finished sealing cycle. In case of an error or deviation the seal cycle is stopped and an alarm will notify you.

Durable design

The easy-to-clean housing is made from stainless steel (AISI 304). The powerful seal bars are designed for heavy-duty use and generate a strong 8 mm seal over the entire length.

Validation of the process variables

The Audion MEDSEAL® is a validatable medical impulse sealer that requires verification of all seal process variables at regular basis. Audion offers a wide range of verification instruments that enable you to verify the critical seal parameters.

- Available verification instruments include:

- ATM (Audion Temperature Meter) measures and verifies the sealing temperature

- AFMR (Audion Force Measurement Ring) measures and verifies the sealing pressure

- Seal Integrity Test (SIT): a service which includes seal check, dye penetration test and peel test

- Calibration: a service (incl. Calibration Certificate) that certifies the preciseness of the sealing parameters of your packaging machine

- Validation documents:

- Installation Qualification (IQ) ensures that the machine is in good condition and functionality, and is calibrated

- Operational Qualification (OQ) optimizes the machine to create quality seals with customers' packaging materials

Benefits

The Audion MEDSEAL® gives you as an end-user the following benefits

- Controlled seal parameters:

- Seal temperature, seal time and seal pressure are fully controlled.

- Easy to install:

- No external air needed due to integrated electromagnets performing a strong seal pressure.

- Monitoring:

- Alarm when a parameter is out of range.

- User-convenience:

- Easy-to-use digital control panel (1 recipe).

- Heavy duty design:

- Stainless steel design and strong 8 mm seal.

- Easy-to-clean:

- Durable stainless steel housing (AISI 304).

Options

The following options are available on the MEDSEAL®

- Verification equipment:

- Audion offers various devices to verify the temperature (ATM) and seal pressure (AFMR) of your seal.

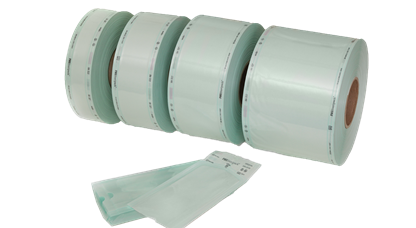

- Tubular film configuration:

- Cutting device (cutting length max. 370mm/500 mm) and film roll holder.

- Foot operation:

- Facilitating both hands free to hold/guide the package.

- Work table:

- Stainless steel work table suitable for both the 460 and 611 model.

- Alternative voltage:

- 115V version.

- Calibration:

- Calibration executed by Audion's service dept. (Audion recommends re-calibration every year).

- IQ/OQ:

- Includes max 2 days work on site - travelling excluded.

Spare parts

Discover the available Audion original quality spare parts for your Medseal® (MSIDV).

- Spare parts

- ← Click to select the required spare parts for your Medseal®

Specifications

More specifications of the Audion MEDSEAL - MSIDV

- Seal width:

- 8 mm

- Seal length:

- 460 or 610 mm

- Type of machine:

- Validatable medical impulse sealer

- Type of seal:

- Temperature-, time- and force controlled impulse seal

- Covering:

- Stainless steel (AISI 304)

- Knife:

- Yes, optional

- Type of film:

- PP (Polypropylene), PE (Polyethylene), Paper-PP, Medical Pouches

Explore our options

Customize your MSIDV to your needs

Convenient worktable

A convenient support table for your products, applicable for both 460 MSIDV and 611 MSIDV

Cutting device

Removes the residual film above the seal. Can be used to create custom bags from tubular film or for ready-made bags.

Calibration

Calibration executed by Audion's service department with validated equipment

IQ/OQ

Installation- and operational quality test on site to ensure the sealing performance

Related products

Let's have a chat!

Do you want to know what the MEDSEAL® - Medical Impulse Sealer can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion