Products

Audionvac VM 203

Medium-sized floor model vacuum chamber with aluminum deep chamber and lid with monitoring window

Interested in our Audionvac VM 203?

We are more than willing to support you with your request or run a demo with your packaging

Outstanding performance and efficiency

This medium-sized floor model vacuum chamber is ideal for efficient and reliable packaging of multiple products. The standard two seal bar configuration enables you to process several batches at once, increasing your output and efficiency.

These configurable Audionvacs are well suited to safely pack food and non-food products, such as high-tech parts and other electrical components. An optional ESD (Electrostatic Discharge) feature enables you to safely pack electrostatic products, e.g. wafers, chips, motherboards and prints.

To meet your product requirements, various other options are available to seamlessly integrate this vacuum chamber into your production line.

The high lid with monitoring glass enables to supervise the overall packaging process. And how beneficial it is to always have the ideal settings at hand for each different product/film type, by means of a user-friendly digital control panel with 10 program memory.

To sum up:

- Configurable to your product and packaging requirements

- Digital control panel (time controlled, 10 programs)

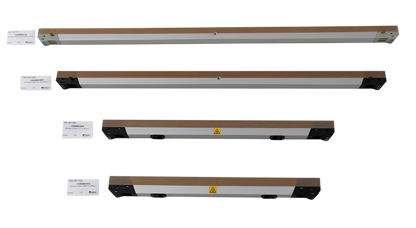

- Two seal bars (left-right, 2 seal wires per seal bar)

- Powerful vacuum pump (63 m3/h)

- Aluminum lid with monitoring glass

- Aluminum deep chamber

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Unique design and optimized convenience

The sunken aluminum chamber creates extra space for larger packages to be sealed and the ability to store 10 seal programs on the device's memory enables the quick restart of production when switching to different sized products or film types.

Consistent high sealing integrity and hygienic efficiency

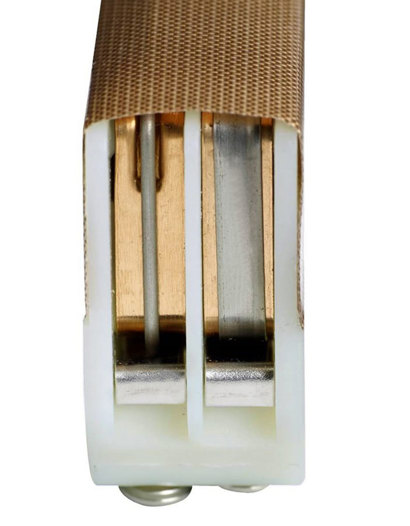

Standard equipped with double rounded (Convex) seal wires of 2 x 3.5 mm that pushes liquid or powdery contents to the side, ensuring a powerful airtight seal over the entire length and thus guaranteeing optimum hygiene and quality preservation of your product.

Monitorable packaging process

Guarantees a continuous high seal integrity after each completed packaging cycle. To double check the correct package position and monitor the packaging process you can use the large sight glass in the aluminum lid.

Seamless addition to your production process

Select from a variety of standardized options such as Electrostatic Discharge (ESD), sensor control or liquid control. All to protect and optimize the quality of your product and maximize efficiency and user-convenience.

Aluminum single chamber vacuum packaging machine

The Audionvac VM 203 floor standing vacuum packaging machine. This vacuum packaging machine has a strong solid aluminum vacuum chamber with an aluminum lid. Standard equipped with:

- Time control

- Soft air to vacuum seal sharp products

- 63 m3/h vacuum pump

- Double seal (2 convex sealing wires)

- 2 seal bars left and right

- 10 program memory

- Insert plate included for a faster cycle and product adjustment

- 3 year warranty

Benefits

The Audionvac VM 203 gives you as end-user the following benefits

- Maximum efficiency:

- Standard 2 seal bars for optimized output.

- Optimum hygiene:

- Standard double seal (2 wires); convex sealing wires for safer sealing results.

- Time control:

- To set the time for vacuum, gas and seal cycles for a constant and guaranteed end result.

- Soft air:

- To pack fragile or sharp products without damaging the products and the bag.

- 10 program memory:

- Quick selection of the correct program for your products.

- Fast cycle:

- Insert plate is standard included, to create a faster cycle and/or to create a better product positioning.

- Ease of use:

- User friendly digital control panel, plug and play.

- Multicycle:

- Alternate vacuum and gas flush (max 5 cycles) in order to reduce the residual oxygen level. Supplied with gas flush option.

- Vacuum pump:

- 63 m3/h vacuum pump for a fast packaging cycle.

- Aluminum lid with sight glass:

- To supervise the proceeding packaging process.

- Deep aluminum chamber:

- For vacuum packaging of higher products.

- Maintenance friendly:

- Easy pump maintenance and cleaning program; Silicone holders are easily removable for cleaning and maintenance.

- Construction:

- High quality material, maintenance friendly and easy to clean construction.

- Warranty:

- 3 years.

Options

The following options are available on the Audionvac VM 203

- Cut-off seal:

- Cut-off seal consists of one 3,5 mm convex seal wire and one 1,1 mm round cutting wire to easily tear off the residual plastic.

- 1-2 cut-off seal:

- Same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Wide seal:

- 10 mm flat seal for a more aesthetic and professional sealing result.

- Bi-active seal:

- Recommend to use when vacuum sealing aluminum or thicker bags. The vacuum bag is being sealed from both sides of the bag.

- ESD (Electrostatic Discharge):

- To pack electrostatic products such as wafers, chips, motherboards and prints. When ESD occurs during the vacuum packaging cycle, it can cause damage to your product. The Audion ESD technology prevents this.

- Aluminum end blocks:

- For heavy duty packaging. Ensure an efficient and durable vacuum packaging process under the most extreme conditions.

- Sensor control:

- The vacuum cycle will stop when the exact end vacuum level has been reached. In this way a constant and guaranteed vacuum is reached.

- Liquid control:

- The liquid control sensor detects the evaporation of the liquid product. The machine then stops extracting the air and proceeds automatically with the next phase, the sealing of the vacuum bag.

- Set of 2 inclined plates:

- Enables liquid products to be placed in an angle to avoid the bag content from spilling.

- Gas flush:

- Enables Modified Atmosphere Packaging (MAP): a gas or nitrogen can be added for optimizing shelf life or realizing extra protection of your product.

- Number of gas nozzles:

- Per sealing bar - left/right (3/3).

- Alternative power supply:

- 230V-1P-50Hz | 220V-1P-60Hz | 200V-3P-50/60Hz | 220V-3P-60Hz

Spare parts

Discover the available spare parts for your VM 203. Audion original quality.

- Spare parts

- ← Click to select the required spare parts for your VM 203

Specifications

More specifications of the Audionvac VM 203

- Seal bar left-right:

- 520 / 520 mm

- Seal width:

- 2 x 3,5 mm double seal (convex sealing wires)

- Effective chamber size (LxWxH):

- 520 x 500 x 235 mm

- Pump capacity:

- 63 m3/h

- Digital control panel:

- 10 program memory

- Machine cycle:

- 15 – 40 sec

- Chamber material:

- Aluminum lid with sight glass and deep aluminum chamber

- Housing material:

- Stainless steel

- Type of film:

- PA/PE, vacuum bags

- Power supply:

- 400V-3P-50Hz (standard)

- Thickness of film:

- 2 x 150 micron

- Power consumption:

- 1,8 kW

- Weight:

- 163 kg

- Machine dimensions (LxWxH):

- 695 x 682 x 1060 mm

Explore our options

Customize your Audionvac VM 203 to fit it to your needs

Bi-active seal

Ideal for vacuum sealing laminated and/or thicker film types to supply the extra heat needed to penetrate isolating laminates / film thickness.

Heavy duty packing

Aluminum end blocks ensure an efficient and durable vacuum packaging process under the most extreme conditions.

Cut-off or 1-2 cut off seal

Cut-off seal, to easily tear off the residual film. 1-2 Cut off seal, same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

ESD (Electrostatic Discharge)

Enables the safe and carefree vacuum packaging of delicate electronical parts, e.g. RAM, graphic cards, or other electronic components. This feature prevents damage by sudden ESD and safeguards your product quality during the packaging process.

Let's have a chat

Do you want to know what the Audion VM 203 can offer for your company? Please feel free to contact us as we are looking forward to explore together which packing solutions benefits you most.

International Sales

Audion