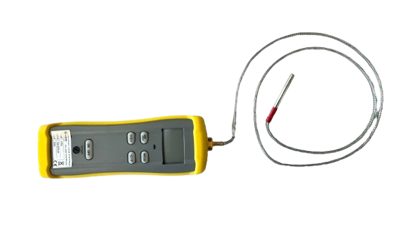

Audion Temperature Measurement with Round Probe (ATM-R)

For validatable continuous band sealers - D 542 AHSV | D 542 AVTSV

Choose a country to view content specific to your geographical location

Products

Accurate temperature measurement to verify the exact seal temperature of Audion's temperature controlled industrial sealers and validatable vacuum chambers.

We are more than willing to support you with your request.

With this sophisticated device, you can measure the temperature between the sealing wires and adjust the machine in accordance with the measured values. The seal temperature always needs to be adjusted after replacing sealing wire. The Audion ATM facilitates accurate adjustment of the seal temperature of your industrial sealer.

The ATM can be used for the complete range of Audion's temperature controlled industrial sealers, as for Audion's validatable vacuum chambers.

The Audion validatable packaging machines require calibration, verification and validation services on a regular basis. Audion offers a wide range of instruments and solutions enabling users to test and verify their packaging machines and seal integrity, in order to meet the high market requirements.

Seal Integrity Test (SIT) as a service which includes:

Please see below more specifications of the ATM:

Do you want to know what the ATM can offer for your company? Please feel free to contact us as we are are looking forward to explore together which packaging solution will benefit you most.

International Sales

Audion

Sales United Kingdom

Audion

Please fill in the below form and we will respond to you as soon as possible.