Products

VMS 223

The ideal heavy-duty vacuum solution to securely pack high volumes of food or non-food

Interested in our VMS 223?

We are more than willing to support you with your request or run a demo with your packaging

Top quality and capacity in vacuum food packaging

The Audionvac VMS 223 with its sunken chamber and double seal bar configuration is perfect for vacuum packing high volumes of medium-large sized products. A convenient transparent high lid allows you to monitor the packing process to ensure it is completed to your satisfaction.

Built to last, its robust stainless steel body and chamber with rounded corners are both hard-wearing and easy to clean. The powerful, low-maintenance vacuum pump (63 m3/h) performs an excellent vacuum to preserve your products in perfect conditions while maintaining excellent quality.

This promising vacuum machine is fully customizable to suit your specific requirements regarding product characteristics and operations. Various specialized options are available to ensure the highest level of user comfort, whilst maximizing your output to achieve the best possible match.

To sum up:

- Configurable packaging solution

- Easy-to-clean stainless steel chamber

- Transparent high lid, for extra chamber volume and monitoring

- Powerful 63 m3/h vacuum pump, low in maintenance

- Suitable to vacuum seal liquids, meat, fish, fruit, vegetables or nuts, including food in jars and food containers.

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Fully HACCP compatible

This packaging solution fully complies to the high requirements of the HACCP (Hazard Analysis Critical Control Point), a generally accepted practice used in the food production/processing industry. Your food quality and safety are our highest priority.

Extra visual control

The flat transparent lid allows you to monitor the packaging process from beginning-to-end. This enables you to actively prevent unpleasant surprises, product-waste and production time losses.

Maximizes your output

This configurable vacuum chamber is designed for ultimate seal performance and optimal workflow. With standard two integrated seal bars (each with 2 seal wires), more products can be vacuumed in one packaging cycle. In addition, the powerful vacuum pump is maintenance-friendly and ensures short cycle times.

Plug and play

Thanks to the easy-to-use digital control panel, you can integrate the machine into your production process with only very minimal training. When working with different product sizes or packaging materials, you can store unique settings per product in up to 10 programs.

The Audionvac VMS 223 offers more product space

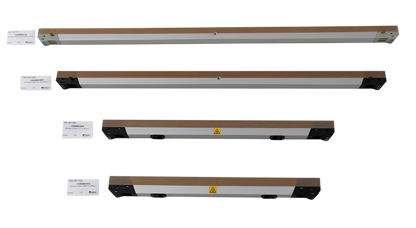

Ideal for high volume operations looking for optimum production with limited space requirement. Advanced technology, left and right seal bars or even a long frontal seal bar of 590 mm is possible. Just modify it to your needs so you can't go wrong. Standard supplied with:

- Time control

- Soft air to vacuum seal sharp products

- Powerful vacuum pump (63 m3/h)

- Double seal (2 convex sealing wires)

- Digital control panel with 10 program memory

- Insert plate included for a faster cycle and product adjustment

- 3 years warranty

Benefits

The Audion VMS 223 gives you the following benefits

- Maximum efficiency:

- Standard 2 seal bars (left/right) to optimize your output.

- Optimum hygiene:

- Standard double seal (2 wires); convex sealing wires for safer sealing results.

- Time control:

- To set the time for vacuum, gas and seal cycles for a constant and guaranteed end result.

- Soft air:

- To pack fragile or sharp products without damaging the products and the bag.

- 10 program memory:

- Quick selection of the correct program for your products.

- Fast cycle:

- Insert plate is standard included, to create a faster cycle and/or to create a better product positioning.

- Ease of use:

- User friendly digital control panel, plug and play.

- Multicycle:

- Alternate vacuum and gas flush (max 5 cycles) in order to reduce the residual oxygen level. Supplied with gas flush option.

- Vacuum pump:

- 63 m3/h vacuum pump for a fast packaging cycle.

- Maintenance friendly:

- Easy pump maintenance and cleaning program; seal bars are easily removable for cleaning and maintenance.

- Lid:

- High transparent lid, increases your capacity and package size flexibility.

- Chamber:

- Stainless steel easy to clean deep chamber - for medium-large sized packages.

- Warranty:

- 3 years.

Options

The following options are available on the Audion VMS 223

- Cut-off seal:

- Cut-off seal consists of one 3,5 mm convex seal wire and one 1,1 mm round cutting wire to easily tear off the residual plastic.

- 1-2 cut-off seal:

- Same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Wide seal:

- 8 mm flat seal for a more aesthetic and professional sealing result.

- Sensor control:

- The vacuum cycle will stop when the exact end vacuum level has been reached. In this way a constant and guaranteed vacuum is reached.

- Liquid control:

- The liquid control sensor detects the evaporation of the liquid product. The machine then stops extracting the air and proceeds automatically with the next phase, the sealing of the vacuum bag.

- Inclined plate:

- Enables liquid products to be placed in an angle to avoid the bag content from spilling.

- Gas flush:

- Enables Modified Atmosphere Packaging (MAP): a gas or nitrogen can be added for optimizing shelf life or realizing extra protection of your product.

- Number of gas nozzles:

- Per sealing bar - left/right (3/3); front (3).

- External pump:

- Vacuum pump and vacuum chamber are separated from each other to avoid evaporation of particles by the vacuum pump in the same room. Used in cleanroom where small particles can affect the manufacturing and quality of a product or assembly.

- Power supply:

- 230V-1P-50Hz | 220V-1P-60Hz | 200V-3P-50/60Hz | 220V-3P-60Hz

Spare parts

Discover the available spare parts for your VMS 223. Audion original quality.

- Spare parts

- ← Click to select the required spare parts for your VMS 223

Specifications

More specifications of the Audion VMS 223

- Seal bar left-right:

- 520 / 520 mm (standard)

- Seal bar front:

- 600 mm

- Seal width:

- 2 x 3,5 mm double seal (convex sealing wires)

- Effective chamber size (LxWxH):

- 520 x 500 x 200 mm (standard)

- Pump capacity:

- 63 m3/h

- Digital control panel:

- 10 program memory

- Machine cycle:

- 15 – 40 sec

- Chamber material:

- Deep drawn stainless steel chamber and high transparent lid

- Housing material:

- Stainless steel

- Type of film:

- PA/PE, vacuum bags

- Thickness of film:

- 2 x 150 micron

- Power supply:

- 400V-3P-50Hz (standard)

- Power consumption:

- 1,8 kW

- Weight:

- 165 kg

- Machine dimensions (LxWxH):

- 710 x 700 x 1025 mm

Explore our options

Customize your VMS 223 to your needs

Modified Atmosphere Packaging (MAP)

Adding gas provides extra protection from discoloration and also prolongs the shelf life of your products. There is a noticeable increase in demand for argon (Ar), as it has the same properties as nitrogen (N2), but in most cases a mix of nitrogen (N2) and carbon dioxide (CO2) is applied. Optionally, Oxygen (O2) can also be added.

Sensor controlled vacuum level

Sensor control stops the vacuum cycle when the pre-set vacuum level has been reached. You can either choose to set the critical vacuum parameter in Mbar, hPa or percentage. This ensures your products are provided with the proper protection and vacuum level and you benefit from a high-efficient workflow.

Optimized production process and product protection

Adaptable to both the product/batch size and the desired/required seal type. For example: Cut-off seal or 1-2 cut off seal (seal and cutting wire can be managed separately), to easily tear off the residual film above the seal.

Liquid control

The Liquid control sensor detects the evaporation point of the liquids (f.i. soups & sauces). It exactly detects when to stop extracting the air and automatically proceeds with the next phase, the sealing of the vacuum bag, preventing drying out of the product, losing weight and contaminating the chamber.

Let's have a chat

Do you want to know what the Audion VMS 223 can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion