Products

Audionvac VMS 263

Industrial double vacuum chamber with powerful 100 m3/h vacuum pump

Interested in our Audionvac VMS 263?

We are more than willing to support you with your request or run a demo with your packaging

Guarantees quality over and over

The VMS 263 is an industrial and robust double vacuum chamber on which extensive options can be integrated to suit your products ideally. The construction of the Audionvac 263 is sturdy and ensures reliability in operation and low maintenance costs.

The Audionvac 263 is equipped with two vacuum chambers and one chamber lid for faster packaging speed. The chamber lid can be moved manually, so the two vacuum chambers work in turn to improve packaging efficiency by 50% more than a single chamber vacuum packing machine.

To sum up:

- Improved ergonomics

- Optimal production output

- Extensive range of customized options

- Guaranteed operational safety

- 100 m3/h vacuum pump

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Operate it like your smartphone

The Audionvac VMS 263 is equipped with a digital control panel. This control panel is clearly laid out and easy to program. Multiple programs can be stored and recalled in order to have the same packing cycle. All to operate it as easy and safe as possible.

We understand this!

Get the best packing result. In the end the end result is one of the most important factors in the packing cycle. You would like to have you product safe, prolonging the product’s shelf life, saving space for storage and shipping and well-presented at your end-user. We understand this! Soft-air, sensor control, gas flush, filler plates, vacuum & gas speed regulation, liquid control etc. can all be built in to guarantee the best packing result.

Easy to clean easy to maintain.

The Audion VMS 263 has a hygienic construction which ensures quick cleaning. The materials used are from a high grade and built into the VMS 263 in an effective way to ensure heavy duty operating of the machine. Basic maintenance is sufficient resulting into low maintenance costs and a high life cycle of the machine.

Reliable, durable and stainable

In today’s world, everyone relies on their products. It is crucial that equipment functions with highly efficient performance. When they fail to do so, it can lead to the customer being exasperated. Therefore, Audion offers a warranty period of 3 years on the Audionvac VMS 263. Spare parts are easy and widely available. This guarantees a safe and reliable functioning of your machine for now and for the future.

Quality seal since 1947

Audion is a leading manufacturer of sealing equipment. It all began in 1947 alongside the famous Dutch channels. Today we have two modern production sites in the Netherlands and Germany were we manufacture machines which are built to last.

Focusing on the end-users comfort and guaranteeing the best, save and most reliable outcome.

The VMS 263 is richly equipped as standard with:

- Time control

- Soft air to vacuum seal sharp products

- 100 m3/h vacuum pump

- Double seal

- Standard 2 seal bars front and back which doubles your packing capacity

- 10 program memory

- Maintenance friendly and easy to clean construction

- 3 year warranty

Benefits

The Audionvac VMS 263 gives you the following benefits

- Maximum efficiency:

- Standard 2 seal bars for optimized output.

- Optimum hygiene:

- Standard double seal (2 wires); convex sealing wires for safer sealing results.

- Time control:

- To set the time for vacuum, gas and seal cycles for a constant and guaranteed end result.

- Soft air:

- To pack fragile or sharp products without damaging the products and the bag.

- 10 program memory:

- Quick selection of the correct program for your products.

- Ease of use:

- User friendly digital control panel, plug and play.

- Multicycle:

- Alternate vacuum and gas flush (max 5 cycles) in order to reduce the residual oxygen level. Supplied with gas flush option.

- Vacuum pump:

- 100 m3/h vacuum pump for a fast packaging cycle.

- Maintenance friendly:

- Easy pump maintenance and cleaning program; Silicone holders are easily removable for cleaning and maintenance.

- Flat working plate:

- Stainless steel, for optimized cleaning and hygiene.

- IP rating:

- IP65 control panel.

- Contruction:

- High quality material, maintenance friendly and easy to clean construction

- Warranty:

- 3 years.

Options

The following options are available on the Audionvac VMS 263

- Cut-off seal:

- Cut-off seal consists of one 3,5 mm convex seal wire and one 1,1 mm round cutting wire to easily tear off the residual plastic.

- 1-2 cut-off seal:

- Same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Wide seal:

- 10 mm flat seal for a more aesthetic and professional sealing result.

- Bi-active seal:

- Recommend to use when vacuum sealing aluminum or thicker bags. The vacuum bag is being sealed from both sides of the bag.

- Aluminum end blocks:

- For heavy duty packaging. Ensure an efficient and durable vacuum packaging process under the most extreme conditions.

- Sensor control:

- The vacuum cycle will stop when the exact end vacuum level has been reached. In this way a constant and guaranteed vacuum is reached.

- Advanced control system:

- To optimize efficiency in food packaging: marinating, tenderizing and red meat functions integrated.

- Liquid control:

- The liquid control sensor detects the evaporation of the liquid product. The machine then stops extracting the air and proceeds automatically with the next phase, the sealing of the vacuum bag.

- Inclined plate:

- Enables liquid products to be placed in an angle to avoid the bag content from spilling.

- Gas flush:

- Modified atmosphere packaging (MAP).

- Number of gas nozzles:

- Per sealing bar - front/back (4/4).

- External pump:

- Vacuum pump and vacuum chamber are separated from each other to avoid evaporation of particles by the vacuum pump in the same room. Used in cleanroom where small particles can affect the manufacturing and quality of a product or assembly.

- Filling plates for lid:

- Reduces the volume of the chamber and shortens the cycle time.

- Power supply:

- 200V-3P-50/60Hz | 220V-3P-60Hz

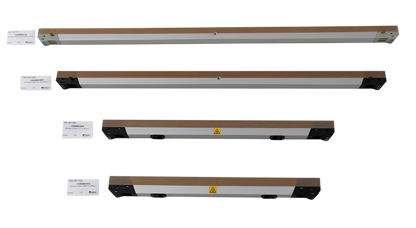

Spare parts

Discover the available spare parts for your VMS 263. Audion original quality.

- Spare parts

- ← Click to select the required spare parts for your VMS 263

Specifications

More specifications of the Audionvac VMS 263

- Seal bar front-back:

- 620 / 620 mm

- Seal width:

- 2 x 3,5 mm double seal (convex sealing wires)

- Effective chamber size (LxWxH):

- (2x) 500 x 620 x 240 mm

- Pump capacity:

- 100 m3/h

- Machine cycle:

- 15 – 40 sec

- Chamber material:

- Stainless steel lid and chamber

- Housing material:

- Stainless steel

- Type of film:

- PA/PE, vacuum bags

- Thickness of film:

- 2 x 150 micron

- Power supply:

- 400V-3P-50Hz (standard)

- Power consumption:

- 2,6 - 3,5 kW

- Weight:

- 345 kg

- Machine dimensions (LxWxH):

- 920 x 1480 x 1100 mm

Explore our options

Customize your Audionvac VMS 263 to your needs

Cut-off or 1-2 cut off seal

Cut-off seal, to easily tear off the residual film. 1-2 Cut off seal: same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

Sensor control

Vacuum packaging machines equipped with Sensor control calculate when the pre-set vacuum percentage has been achieved. This guarantees a constant end vacuum of your package.

Heavy duty packing

Aluminum end blocks ensure an efficient and durable vacuum packaging process under the most extreme conditions.

External pump

The pump can be placed outside of the machine frame with a long hose connection. This option is for example very suitable to apply in a clean room.

Filling plates

By using the filling plates for the lid of the double chamber models, the volume of the chamber decreases. The benefit is that the cycle time becomes shorter and the gas consumption decreases.

Bi-active seal

Used when vacuum sealing aluminium or thicker bags. This seal system has seal bars on both the inside of the lid and on the front of the vacuum chambers, so the vacuum bag is being sealed from both sides of the bag.

Let's have a chat

Do you want to know what the Audionvac VMS 263 can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most

International Sales

Audion