Products

Validatable VMS 503

XL validatable double-chamber Audionvac that offers a high level of seal integrity, consistent vacuum results and convenience

Interested in our Validatable VMS 503?

We are more than willing to support you with your request or run a demo with your packaging.

Engineered to provide utmost packaging integrity

The validatable VMS 503 is an extra large double vacuum chamber from the validatable Audionvac range. This floor model features an easy-to-clean two flat bed chamber for easy cleaning. The stainless steel swinging high lid and 2 sets of double seal bars allow you to safely pack larger items and multiple items in one cycle for optimum efficiency and production output.

The Audion Touch Techware with integrated Temperature Controller offers you full control over the process variables: vacuum/gas pressure, seal temperature, seal time and seal pressure. An alarm function automatically aborts the sealing cycle when a deviation in the process variables occurs during monitoring. All critical seal data can be recorded and exported to a PC for traceable storage using a USB stick.

Vacuum pressure and gas pressure are controlled and monitored by sensors to guarantee the set required vacuum level is consistently achieved, thereby ensuring the safety and quality of your products.

The high pressure bi-active sealing bars produce an 8 mm hermetic seal, ensuring optimum reliability for demanding industries that require utmost seal integrity.

The validatable VMS 503 is compliant to ISO 11607-2 being applicable to industry, life science, and medical device packaging operations.

To sum up:

-

- Double chamber solution for optimum efficiency and output

- 2 sets of bi-active 8mm impulse seal bars

- Adjustable parameters - To ensure high quality seals and a consistent required vacuum level each finished cycle

- 2 easy-to-clean flat bed chambers, stainless steel swinging high lid - for larger sized items/batches

- Equipped with user friendly touchscreen interface (ADC) with memory feature for 50 recipes and data export via USB

- Alarm function with cycle stop

- Various configurable options/accessories available

- Complies to ISO 11607-2 validation requirements

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business.

Optimized efficiency

Dual flat bottom chambers and a swinging high lid provide the ability to pack large or multiple items in one cycle. You can pack your products with double the speed of a single chamber Audionvac by preparing a chamber during the seal cycle of the other. The swinging lid is easy-to-use and accomodates medium to large (batch) packaging productions. A wide selection of options and accessories is available to ensure seamless integration into your packaging process and to guarantee your products meeting the required quality standards.

User-friendly Audion touchscreen control panel

The user-friendly Audion Touch Techware control panel can store up to 50 different recipes of process variables that contain the optimal settings for each of your products. Therefore, the right settings are always at hand to optimize your workflow and prevent production errors. This allows you to easily switch from one batch to another, control your production at a high level and increase your efficiency. The easy-to-read display visualizes your settings and process variables to analyze during the sealing process.

Alarm function

Sensors activate the alarm function and abort the packaging cycle in case one of the process variables has exceeded the alarm limit. The acceptable tolerance of the critical parameters can be set individually for each process parameter. Once the relevant parameter deviates from its set tolerance the machine will stop operating. This feature actively supports the packaging process by preventing errors and ensures that the packaging standards for your product are met.

Cleanroom compatible

The validatable Audionvac VMS 503 can be implemented in sterile environments and clean rooms by configuring the machine with a dry vacuum pump or by installing the standard oil-pump outside the clean room. To further ensure product safety, all data with the critical process variables can be exported and logged by means of a USB stick. The data content can then be transferred to a PC to be analyzed for various purposes.

Verification of process variables

The Audion VAL VMS 503 is a validatable double vacuum chamber that requires verification of all process variables on a regular basis. Audion offers a wide range of verification instruments that enable companies to verify their process variables.

- Available verification instruments include:

- ATM (Audion Temperature Meter) measures and verifies the sealing temperature

- ASPM (Audion Seal Pressure Measurement) measures and verifies the sealing pressure

- AVLM (Audion Vacuum Level Measurement) measures and verifies the vacuum pressure

- Seal Integrity Test (SIT) as a service which includes seal check, dye penetration test and peel test

- Calibration as a service (incl. calibration certificate) certifies the preciseness of the process variables of the packaging machine

- Validation documents:

- Installation Qualification (IQ) ensures that the machine is in good condition and functionality, and is calibrated

- Operational Qualification (OQ) optimizes the machine to create quality seals with customers packaging materials

Benefits

The Audion VAL VMS 503 gives you as an end-user the following benefits:

- Most accurate validation:

- The validation function integrated in the Audion Touch Techware ensures the highest accuracy of validation. It most precisely monitors and controls all critical process variables: vacuum/gas pressure, seal temperature, seal time and seal pressure. Tight tolerance settings make validatable Audionvac models unmatched when compared to other packaging solutions.

- Maximum efficiency:

- Double chamber solution with 2 sets of seal bars and low friction motion for optimized output.

- Optimum hygiene:

- Standard bi-active 8 mm impulse sealbars and easy-to-clean flat bed chambers.

- Maintenance friendly:

- Seal bars are easily removable for cleaning and maintenance.

- Chambers:

- Stainless steel easy to clean flat bed and high lid - for medium/large batch productions/product sizes.

- Alarm function:

- Generates an alarm and stops the operation when a process variable deviates from the pre-set acceptable tolerance.

- 50 program memory:

- Quick selection of the correct program for your products.

- Soft air:

- To pack fragile or sharp products without damaging the products and the bag.

- Vacuum pump:

- 300 m3/h vacuum pump for a fast packaging cycle.

- Conditioning program:

- If the machine is not used continuously for a certain time, the vacuum pump does not reach the ideal temperature. The moisture contained in the air sucked by the pump stays in the oil, and may lead to condensation inside the pump, which can eventually cause corrosion. To keep the pump and oil in good condition, there is a pump conditioning program available in the control system.

Options

The following options are available on the VAL VMS 503:

- (Re-)Calibration service:

- Audion provides calibration services for our validatable sealers. The critical process parameters (seal temperature, seal force, seal time/speed, etc.) are measured with traceable measuring devices and a calibration certificate will be issued.

- Easy swing lid:

- Improves egonomics by reducing force required to swing the lid.

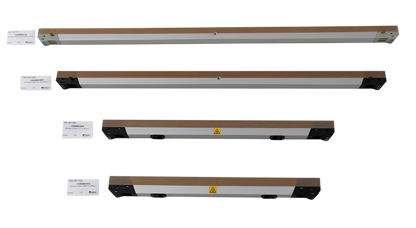

- Seal bar left-right:

- 820 / 820 mm (standard = front-back 1080 / 1080 mm).

- Gas flush:

- Enables Modified Atmosphere Packaging (MAP): a gas or nitrogen can be added for optimizing shelf life or realizing extra protection of your product.

- External exhaust:

- Vacuum pump and vacuum chamber are separated from each other to avoid evaporation of particles by the vacuum pump in the same room. Used in cleanroom environments where small particles can affect the manufacturing and quality of a product or assembly.

- External pump:

- Vacuum pump and vacuum chamber are separated from each other to avoid evaporation of particles by the vacuum pump in the same room. Used in cleanroom where small particles can affect the manufacturing and quality of a product or assembly.

- User administration:

- Personal login ID, password, and user level assignment.

- Multicycle:

- Alternate vacuum and gas flush (max 5 cycles) in order to reduce the residual oxygen level. Supplied with gas flush option.

- Barcode scanner:

- Quick recipe change by scanning a barcode.

- Label printer:

- For printing tracing information on labels and apply on bags.

- Measuring & testing equipment:

- Equipment to measure performance of your seal or packaging machine.

- Operation panel on extended arm:

- For ergonomic operation and easy check of the process.

- Alternative power supply:

- 200V-3P-50/60Hz | 220V-3P-60Hz

Spare parts

Discover the available spare parts for your VMS 503. Audion original quality.

- Spare parts

- ← Click to select the required spare parts for your VMS 503

Calibration/Verification/Validation

Discover the available equipment and services for your Validatable VMS 503.

- Calibration/Verification/Validation

- ← Click here to learn more about our services and verification equipment

Specifications

Please see below more specifications of the Audionvac VAL VMS 503:

- Seal bar front-back:

- 1080 / 1080 mm (standard)

- Seal bar left-right:

- 820 / 820 mm

- Seal width:

- 8 mm bi-active

- Effective chamber size (LxWxH):

- (2x) 730 x 1080 x 280 mm (standard)

- Pump capacity:

- 300 m3/h

- Controlled process variables:

- Vacuum/gas pressure, seal temperature, seal time, seal pressure

- Audion Touch Techware:

- High-end validation software with integrated Audion Temperature Controller (ATC), uniquely designed by Audion to meet the most stringest requirements in validatable packaging environments

- 50 program memory:

- Pre-set critical process variable recipes

- Machine cycle:

- 20 - 45 sec

- Chamber material:

- Stainless steel lid and chamber

- Housing material:

- Stainless steel

- Type of film:

- PA/PE, vacuum bags, aluminum laminated bags

- Thickness of film:

- 20 - 400 micron

- Required external air pressure:

- 0,3 MPa

- Power supply:

- 400V-3P-50Hz (standard)

- Power consumption:

- 5,5 – 7,8 kW

- Weight:

- 775 kg

- Machine dimensions (LxWxH):

- 1213 x 2420 x 1597 mm

Explore our options

Customize your VAL VMS 503 to fit your needs

Validation documentation (IQ/OQ)

Installation qualification (IQ) and Operational qualification (OQ). Our team of experts will conduct multiple tests with different scenarios with your pouches to determine that our machine meets the required packaging standards.

User-Administration

User level registration, access rights and user registration can be protected by passwords to keep full control over the seal integrity of your packing processes. Includes: Personal login ID, password, and user level assignment

Label printer

Print important batch information and operator data on labels via a label printer. Once the content is printed on the label, the operator applies the label manually on the packed pouch.

Multi-cycle

Multiple vacuum and gas flush cycles before the seal production. Enables the perfect MAP conditions to preserve prestine product quality and protection.

Pump options for cleanroom use

The oil-pump is placed outside the cleanroom in order to avoid contamination of the sterile environment. As an alternative you can also replace the standard oil pump for an optional dry vacuum pump.

External exhaust

Via the external exhaust you are able to connect an additional hose which will discharge the contaminated air outside of the cleanroom. This feature is suitable for sterile environments in the pharma/medical industry.

Let's have a chat

Do you want to know what the Audion Validatable models can offer for your company? Please feel free to contact us as we are looking forward to explore together which packaging solution will benefit you most.

International Sales

Audion