Products

Audionvac VMS 883

Fully customizable and powerful double vacuum chamber equipped with a flat working plate for optimum hygiene

Interested in our Audionvac VMS 883?

We are more than willing to support you with your request or run a demo with your packaging

Guarantees quality over and over

This strong double chamber vacuum machine with a flat working plate is made from heavy industrial materials for optimum durability. The powerful 300 m3/h pump guarantees enough power to minimize the machine cycle time, making the Audionvac VMS 883 ideal for large scale production applications.

To optimize your workforce, safety and ergonomics an (optional) automatic lid is available moving between both chambers.

The Audionvac VMS 883 is available as a basic industrial model and as a full option vacuum packaging machine with configurable seal bars and advanced options to optimize the quality of various products.

To sum up:

- Suitable for industrial packaging of food- and non-food products

- Improved ergonomics

- Optimal production output (multiple seal bars)

- Guaranteed operational safety

- 300 m3/h vacuum pump

- Fully customizable to create optimized efficiency

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Fully HACCP compatible

The Audionvac VMS 883 meets the high requirements of the HACCP (Hazard Analysis Critical Control Point). This is a generally accepted practice used in the food industry. This ensures you as an operator that all the aspects of food storage and handling are conducted in a safe manner by the Audionvac VMS 883

Intelligent design for long life reliability

The service friendly construction resulting in low maintenance cost for the enduser and all parts are easily accessible. Operators don’t need an extended training as the machine and the way the software is being built up speaks for itself – plug and play.

Easy operation by a single worker

Despite its size the Audionvac VMS 883 offers exceptional packaging flexibility and productivity for a broad variety of meat, poultry, seafood, or dairy products. The easy lid swing is designed for efficient operation by a single worker. It ensures easy closure of the lid with minimal effort of the operator all to produce high quality, low-cost packaging solutions for daily mid/large range production environments.

Precise control system

What determines the perfect package? Control of the critical seal parameters are one of the most important aspects in order to create the perfect package. Thanks to our 10 program control system this will be in hand reach of every company now. Special options and intelligent functions that add significant value to your vacuum packaging operations.

Automatic lid - Improves your workflow

The automatic lid will gain huge competitive advantages;

- Reduces the human error

Any human worker is bound to make errors no matter their resume. One of the key benefits of automatic lid is that it reduces human error as it runs more accurately than humans can. - Be predictable

Consistency is an important part of any process, and it isn’t possible for humans to perform tasks in exactly the same way every time. The automatic lid removes variation from your packing process, giving you consistent results every time. - Brings safety to a next level

Guarantee of safety for the operator is key when using an automatic packaging system. Audion supplies the Automatic lid standard with motion sensors. These will guarantee the highest protection level during the entire vacuum packaging process. - Spend money to save money

Less FTE needed as the Automatic lid reduces the work for the operator. This means that your company does not need to hire extra people to do the work. - Improved ergonomics

Operators experience a huge ergonomic advantage with the automatic lid. Less weight has to be lifted, which improves the working conditions of individual operators and reduces sick leave and stress. - Easier to maintain

The automatic lid doesn’t require much maintenance. It is designed and created with a specific purpose in mind, and they don’t have many moving parts or components that break down easily. - Work faster with less effort

The automatic lid can take care of handlings at a faster pace than operators can, saving packaging time.

And most important of all, the above will result into a better customer satisfaction.

Benefits

The Audionvac 883 gives you as end-user the following benefits

- Maximum efficiency:

- Standard 2 seal bars for optimized output.

- Optimum hygiene:

- Standard double seal (2 wires); convex sealing wires for safer sealing results.

- Time control:

- To set the time for vacuum, gas and seal cycles for a constant and guaranteed end result.

- Soft air:

- To pack fragile or sharp products without damaging the products and the bag.

- Fast cycle:

- Insert plate is standard included, to create a faster cycle and/or to create a better product positioning.

- 10 program memory:

- Quick selection of the correct program for your products.

- Ease of use:

- User friendly digital control panel, plug and play.

- Multicycle:

- Alternate vacuum and gas flush (max 5 cycles) in order to reduce the residual oxygen level. Supplied with gas flush option.

- Vacuum pump:

- 300 m3/h vacuum pump for a fast packaging cycle.

- Maintenance friendly:

- Easy pump maintenance and cleaning program; Silicone holders are easily removable for cleaning and maintenance.

- Flat working plate:

- Stainless steel, for optimized cleaning and hygiene.

- Construction:

- High quality material, maintenance friendly and easy to clean construction.

- Warranty:

- 3 years.

Options

The following options are available on the Audionvac 883

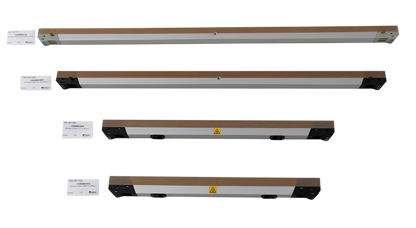

- Cut-off seal:

- Cut-off seal consists of one 3,5 mm convex seal wire and one 1,1 mm round cutting wire to easily tear off the residual plastic.

- 1-2 cut-off seal:

- Same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Wide seal:

- 10 mm flat seal for a more aesthetic and professional sealing result.

- Bi-active seal:

- Recommend to use when vacuum sealing aluminum or thicker bags. The vacuum bag is being sealed from both sides of the bag.

- Aluminum end blocks:

- For heavy duty packaging. Ensure an efficient and durable vacuum packaging process under the most extreme conditions.

- Sensor control:

- The vacuum cycle will stop when the exact end vacuum level has been reached. In this way a constant and guaranteed vacuum is reached.

- Liquid control:

- The liquid control sensor detects the evaporation of the liquid product. The machine then stops extracting the air and proceeds automatically with the next phase, the sealing of the vacuum bag.

- Inclined plate:

- Enables liquid products to be placed in an angle to avoid the bag content from spilling.

- Gas flush:

- Enables Modified Atmosphere Packaging (MAP): a gas or nitrogen can be added for optimizing shelf life or realizing extra protection of your product.

- Number of gas nozzles:

- Per sealing bar - front/back (6/6).

- Filling plates for lid:

- Reduces the volume of the chamber and shortens the cycle time.

- Automatic lid:

- Improves your ergonomics, optimizes your production output and guarantees safety.

- Alternative power supply:

- 200V-3P-50/60Hz | 220V-3P-60Hz

Spare parts

Discover the available spare parts for your VMS 883. Audion original quality.

- Spare parts

- ← Click to select the required spare parts for your VMS 883

Specifications

More specifications of the Audionvac VMS 883

- Seal bar front-back:

- 840 / 840 mm

- Seal width:

- 2 x 3,5 mm double seal (convex sealing wires)

- Effective chamber size (LxWxH):

- (2x) 830 x 840 x 255 mm

- Pump capacity:

- 300 m3/h

- Machine cycle:

- 10 – 30 sec

- Chamber material:

- Stainless steel lid and chamber

- Housing material:

- Stainless steel

- Type of film:

- PA/PE, vacuum bags

- Thickness of film:

- 2 x 150 micron

- Power supply:

- 400V-3P-50Hz (standard)

- Power consumption:

- 5,5 – 6,0 kW

- Weight:

- 685 kg

- Machine dimensions (LxWxH):

- 1295 x 1900 x 1130 mm

Explore our options

Customize your VMS 883 to fit it to your needs

Cut-off or 1-2 cut off seal

To easily tear off the residual film for optimum hygiene. 1-2 cut off seal, same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

Automatic lid

Operators experience a huge ergonomic advantage with the automatic lid. Less weight has to be lifted, which improves the working conditions of individual operators and reduces sick leave. This advanced option includes a foot pedal to enable semi-automatic operation.

10 mm wide seal

Safe wide seal, also giving an aesthetic and professional result.

Gas flush

Injecting a gas before the sealing phase increases the product's shelf life, it offers extra protection and it prevents the product from colouring.

Heavy duty packing

Aluminum end blocks ensure an efficient and durable vacuum packaging process under the most extreme conditions.

Sensor control

Vacuum packaging machines equipped with Sensor control calculate when the pre-set percentage has been achieved. This guarantees a constant end vacuum of your package. Always. Especially recommended when packing various types of products with different volume.

Let's have a chat

Do you want to know what the Audion VMS 883 can offer for your company? Please feel free to contact us as we are looking forward to explore together which packing solutions benefits you most.

International Sales

Audion