Products

Audionvac VMS 903

Fully automatic high-capacity double vacuum chamber with two internal conveyor belts and automatic lid for optimized effficiency

Interested in our VMS 903?

We are more than willing to support you with your request or run a demo with your packaging

Industry leader in cost reducing automated productivity

The Audion VMS 903 is a fully automatic vacuum packaging machine with two internal conveyor belts and an automatic lid as standard. This machine will definitely give your packaging process a big boost! Not only will it optimize your packing process, it will also enable you to produce a higher output with less FTE while guaranteeing a perfectly safely packed product.

This top model Audionvac is equipped with a 20 program memory and Advanced Control System, integrating intelligent functions each adding significant value to your vacuum operation and products.Thanks to the smart software features such as marinating, tenderizing, fast air injection and sequential vacuum are all within reach now.

Taking perfection one step further. Enjoy this high-capacity double chamber model and optimize your operational processes to the max.

To sum up:

- Optimal production output (by multiple seal bars)

- 2 Integrated conveyors for product discharge

- Digital control with 20 programs

- Advanced Control System with sensor

- Fully customizable to create optimized efficiency

- 300 m3/h vacuum pump

- Improved ergonomics

- Guaranteed operational safety

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

More than a control system

The control panel is clearly laid out and easy to program. 20 Programs can be stored and recalled in order to repeat the same packing cycle and ensure consistent product quality. Advanced Control System is standard included, optimizing food products through marinating, tenderizing and various other extra values. All to operate it as easy and safe as possible. The full color screen with intuitive graphic interface and an animated packing cycle will get the best out of the operator.

Less FTE's are needed

Less FTE's are needed as your product is being loaded onto one end of the seamless conveyor while the sealing chamber is in operation at the opposite end. The finished packaged product automatically moves from the sealing chamber to an off load conveyor or shrink tunnel while the loaded conveyor automatically moves into the sealing chamber and the process repeats. Can you imagine the efficiency.

Brings safety to a next level

Guarantee safety for the operator is key when using an automatic packaging system. Audion supplies the automatic lid standard with emergency stop buttons and motion sensors in case of entrapment. These will guarantee the highest protection level during the entire vacuum packaging process.

Create the perfect vacuum package

Control of the critical seal parameters are one of the most important aspects in order to create the perfect vacuum in your bag. Thanks to our powerful control system this will be in hand reach of every company now. Adjust the belt height to match it with your product all to gurantee the best packing outcome.

Taking perfection one step further

Audionvac VMS 903 offers the highest possible packaging output on the market by:

- Reducing the human error

Any human worker is bound to make errors no matter their resume. One of the key benefits of automatic lid is that it reduces human error as it completes tasks more accurately than humans can. - Being predictable

Consistency is an important part of any process, and it isn’t possible for humans to perform tasks in exactly the same way every time. The automatic lid removes variation from your packing process, giving you consistent results every time. - Spend money to save money

Less FTE needed as the Automatic lid reduces the work for the operator. This means that your company does not need to hire extra people to do the work. - Improved ergonomics

Operators experience a huge ergonomic advantage with the automatic lid. Less weight has to be lifted, which improves the working conditions of individual operators and reduces sick leave and stress. - Easier to maintain

The automatic lid doesn’t require much maintenance. It is designed and created with a specific purpose in mind, and they don’t have many moving parts or components that break down easily. - Work faster with less effort

The automatic lid can take care of handlings at a faster pace than operators can, saving packaging time.

Most important of all, the above will result into a higher customer satisfaction.

Benefits

The Audion VMS 903 gives you as end-user the following benefits

- Advanced control system:

- To optimize efficiency in food packaging: marinating, tenderizing and red meat functions integrated.

- 20 program memory:

- Quick selection of the correct program for your products.

- Automatic lid:

- Improves ergonomics, optimizes production output and guarantees safety, operated by foot switch.

- Internal conveyor belts:

- Easy discharge of your vacuumed products. Equipped with quick-release attachment for cleaning, height adjustable.

- Safety:

- Automatic lid system including motion sensor for detecting entrapment. Emergency stop buttons are located on both chambers.

- Maximum efficiency:

- Standard 2 seal bars for optimized output.

- Optimum hygiene:

- Standard double seal (2 wires); convex sealing wires for safer sealing results.

- Soft air:

- To pack fragile or sharp products without damaging the products and the bag.

- Vacuum pump:

- 300 m3/h vacuum pump for a fast packaging cycle.

- Maintenance friendly:

- Easy pump maintenance and cleaning program; Silicone holders are easily removable for cleaning and maintenance.

- Construction:

- High quality material, maintenance friendly and easy to clean construction.

- Warranty:

- 3 years.

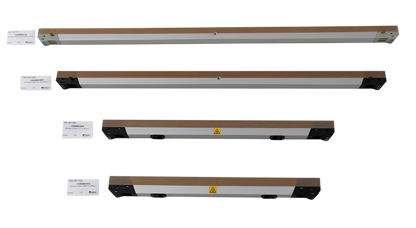

Options

The following options are available on the Audion VMS 903

- Cut-off seal:

- Cut-off seal consists of one 3,5 mm convex seal wire and one 1,1 mm round cutting wire to easily tear off the residual plastic.

- 1-2 cut-off seal:

- Same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

- Liquid control:

- The liquid control sensor detects the evaporation of the liquid product. The machine then stops extracting the air and proceeds automatically with the next phase, the sealing of the vacuum bag.

- Discharge conveyor (LxW):

- 3000 x 600 mm.

- Alternative power supply:

- 220V-3P-60Hz

Spare parts

Discover the available spare parts for your VMS 903. Audion original quality.

- Spare parts

- ← Click to select the required spare parts for your VMS 903

Specifications

Please see below more specifications of the Audion VMS 903

- Seal bar left-right:

- 840 / 840 mm

- Seal width:

- 2 x 3,5 mm double seal (convex sealing wires)

- Effective chamber size (LxWxH):

- (2x) 840 x 890 x 220 mm

- Pump capacity:

- 300 m3/h

- Machine cycle:

- 30 - 50 sec

- Chamber material:

- Stainless steel lid and chamber

- Housing material:

- Stainless steel

- Type of film:

- PA/PE, vacuum bags, shrink bags

- Thickness of film:

- 2 x 150 micron

- Power supply:

- 400V-3P-50Hz (standard)

- Power consumption:

- 5,5 kW

- Air supply:

- 0,6 MPa

- Air consumption:

- 100Nl/min

- Weight:

- 850 kg

- Machine dimensions (LxWxH):

- 1061 x 2420 x 1150 mm

Explore our options

Customize your VMS 903 to fit it to your needs

Liquid control

The Liquid control sensor detects the evaporation point of the liquids (f.i. soups & sauces). It exactly detects when to stop extracting the air and automatically proceeds with the next phase, the sealing of the vacuum bag, preventing drying out of the product, losing weight and contaminating the chamber.

Cut-off or 1-2 cut off seal

Cut-off seal, to easily tear off the residual film for optimized hygiene. 1-2 Cut off seal, same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately

Seal configuration

The right seal configuration protects products safely against external influences. Audion offers several seal configurations in order to fulfil the high demands of our customers.

Discharge conveyor

Add a discharge conveyor to the VMS 903 in order to have a complete system. Audion offers several sizes of conveyors.

Let's have a chat

Do you want to know what the Audion VMS 903 can offer for your company? Please feel free to contact us as we are looking forward to explore together which packing solutions benefits you most.

International Sales

Audion