Precision in Validatable Packaging

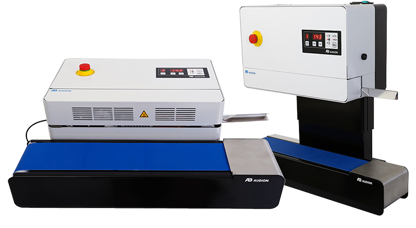

Audion’s D 542 AVTSV is the most reliable vertical band sealer for medical and pharmaceutical packaging applications. Engineered for precision, it delivers the highest level of seal integrity, ensuring that every bag is sealed to perfection. This cutting-edge machine is equipped with Audion Touch Techware, operated via a 7-inch color touchscreen (ADC), offering seamless control over all critical sealing parameters: temperature, pressure, and speed.

Designed for industries where validated, airtight seals are a must, the D 542 AVTSV provides continuous verification of key parameters throughout the production process. Any deviation in temperature, speed, or pressure is instantly flagged with an alarm and the system’s reject mode ensures that bags not meeting the set standards are transported backwards and rejected. This process guarantees that only fully compliant bags proceed, maximizing product safety.

Built from high-quality stainless steel with Audion’s renowned robust design, the D 542 AVTSV offers a compact footprint, making it suitable for integration into production lines or standalone use. Its intuitive, user-friendly touchscreen interface allows operators to easily set up and manage different product recipes, while also providing real-time process management data, alarms, and diagnostics.