Products

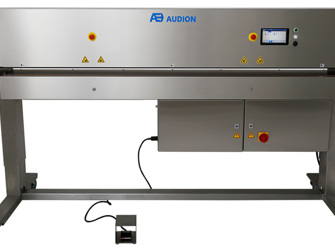

Power Sealer PLUS XL

The Power Sealer PLUS XL is designed for making long and fully controlled hermetic seals

Interested in our Power Sealer PLUS XL?

We are more than willing to support you with your request or run a demo with your packaging

When product size and seal quality are a challenge

PSR XL PLUS is fully validatable: sealing process parameters are monitored for deviation making this an ideal machine for medical, pharma, and other critical packaging applications. The integrated temperature controller ensures that every seal is made at the same temperature, creating the same reliable seal result, even during intensive operation.

The heavy duty construction and high performance bi-active seal bars produce a straight and secure 8 mm seal up to a length of 2500 mm without any concession to seal integrity. Ideal for protecting your largest products with protective film covers to ensure a safe and secure storage or transport within the supply chain.

This pneumatically operated packaging solution can seal most modern film types like PE, aluminum laminated and antistatic film types up to 400 micron.

The optional vacuum system (standard equipped with a powerful and almost maintenance-free 20m3 Venturi pump) is ideal for applications requiring vacuum or modified atmosphere packaging (MAP) of bulk products. This also enables you to minimize the package size and transport/storage costs and to optimally preserve and prolong the quality of your products.

Benefits:

- Well suited for sealing extra long film lengths of custom bags and protective coverings

- Large seal opening (45 mm)

- Temperature controlled sealing ensuring consistent seal results

- Audion Touch Techware integrated: to set up to 50 recipes for each different product /film combination

- Suitable for integration in validated processes

- Excellent Audion services available for both certified (re)calibrations, maintenance and spare parts.

This makes your machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Guaranteed ultimate seal integrity

Extra long bi-active sealbars produce a consistent 8 mm seal over the entire lenght of up to 2500 mm.

Robust and user-friendly by design

Special heavy-duty construction to facilitate intensive use and ultimate performance and reliability.

Uniquely embedded technologies

When combined with validation option, sealing temperature, sealing time and seal force can be controlled, monitored and recorded, realizing a seal integrity of 100%.

Minimizes transport costs and storage space

Extra powerful Venturi pump integrated within the optional vacuum system creating a perfectly fitted protection for your product(s) and reduces the package size.

Video's Power Sealer PLUS XL

An integrated vacuum and/or gas flush system

The PSR PLUS XL can be configured for "sealing only" or with an integrated vacuum system.

The Audion Vacuum Power Sealer PLUS XL is equipped with a 20m3 Venturi pump and extra wide vacuum nozzle enabling a powerful vacuum result, ideal for operating in a continuous packaging process, reducing production time. The pump is virtually maintenance free (operating without oil).

The vacuum system can be combined with gas flush to create modified atmosphere packaging (MAP). The gas flush system ensures safe and quality-controlled packaging of all kinds of products, enabling extended shelf life of food and non-food products and actively prevents the change of metals oxidizing of e.g. electric equipment and devices.

An integrated vacuum system can be used for:

- Volume reduction of the package to save storage and shipment costs

- Applying a modified atmosphere (MAP) to extend the shelf-life of food products

- Prevention of oxidation of, for example, electrical appliances and metal parts

Benefits

The Audion Power Sealer PLUS XL gives you the following benefits

- Powerful 8 mm seal:

- Suitable for sealing most modern film like PE, anti-static film (to make reliable (extra large) bags and sleeves).

- Excellent seal integrity:

- The pneumatic bi-active sealing bars produce a powerful and evenly distributed seal pressure at each sealing cycle to ensure a hermetic seal, even during repetitive use.

- Protected seal cycle:

- No errors can be tolerated. Therefore an integrated 3 level log-in (operator, supervisor and administrator protected seal cycles) comes standard in the Power Sealer XL.

- Optimized output:

- Large lengths of film can be efficiently sealed at once, reducing production time and providing a representative and reliable protection of your products.

- Most advanced validation:

- The optional validation function that is integrated in the Audion Touch Techware reaches the highest degree of validation. It most precisely monitors and controls all critical sealing parameters such as seal temperature, seal time and seal force (precisely measured by 1N). Tight tolerance settings make Power Sealer PLUS XL unmatched when compared to other XL packaging solutions.

Options

The following options are available on the Audion Power Sealer PLUS XL

- Integrated vacuum / gasflush system:

- Reduces package size and/or preserves and extends the shelf life of food or erosion-sensitive products using a virtually maintenance-free powerful built-in 20m3 Venturi pump (if needed in combination with MAP)

- Pneumatic cutting device:

- Enables you to remove the rest film above the seal preventing contamination inside the bag opening

- Calibration certificate by Audion:

- Performed by skilled Audion service engineers in our in-house calibration facility

Accessories

The following accessories are available on the Audion Power Sealer PLUS XL

- Barcode scanner:

- Allows you to quickly scan the ideal seal parameter recipe when sealing different film types / thicknesses

- Set of wearing parts:

- Convenient set for quickly replacing the PTFE, rubber and seal wire to do easy maintenance. To guarantee an optimal sealing result, also after regular use.

Specifications

More specifications of the Audion Power Sealer PLUS XL

- Seal length Power Sealer PLUS XL:

- 2500 mm

- Seal width:

- 8 mm

- Easy-to-operate Audion Touch Techware:

- Equipped with integrated Audion Temperature Controller (ATC)

- Critical seal parameter recipes:

- Up to 50 recipes can be stored

- Downloadable batch information:

- Batch information of critical seal-parameters can be downloaded (USB stick)

- Foot operation:

- Yes

- Configurable to customer specific requirements:

- Yes

- Film type:

- Suitable for sealing various modern film types including thick films and special laminates

- Covering:

- stainless steel covering

- Classification:

- 2014/35/EU Low Voltage Directive, 2006/42/EC Machine Directive, 2014/30/EU EMC-Directive, RoHS 2 2011/65/EU Directive; EN-ISO 11607-2, EN-ISO 12100, EN-ISO 4414, EN-ISO 14118, EN-IEC 60204-1

Explore our options

Customize your Power Sealer PLUS XL to your needs

Optimized Vacuum / Gasflush process

Integration of a venturi vacuum system will enable you to reduce voluminous packaging or extend the shelf life of food or erosion-sensitive products.

Extra seal comfort

A convenient work table supports the weight of longer (slim) objects, leaving the operator's hands free to guide the film straight between the seal bars.

Audion (re)-calibration services

Professional calibration combined with excellent factory machine to calibrate your new or operational validatable sealer and guarantee the highest standards of seal integrity for your customers.

Ultimate hygiene & visual presentation

A pneumatic cutting device is recommendable to minimize dirt or dust inside the bag opening. The residual film above the seal will be cut in this way, creating a nice, clean and straight appearance.

Discover our Power Sealer line:

This no-nonsense Power Sealer forms the solid basis of the renowned Power Sealer line. The outstanding 5 mm sealing performance is achieved by a pneumatic bi-active and time-controlled impulse sealing system. Optional vacuum system feature can be integrated.

This model is validatable and generates an 8 mm temperature- and time controlled seal. The validation enables that critical seal variables like seal force, seal temperature and seal time are being controlled. Optional vacuum system feature can be integrated.

The Power Sealer TC is a high-performance temperature controlled sealing machine designed for demanding packaging needs in the high-tech and food industries. It features a durable stainless steel housing, touchscreen interface, and powerful bi-active and pneumatic seal bars that ensure consistent, airtight seals. Optional vacuum system feature can be integrated.

The next step in the Power Sealer line is the Plus version. With its unique and most precise system of validation it meets todays' most stringent packaging requirements. 8 mm Temperature- , time- and force controlled seal. Includes Audion Touch Techware. Optional vacuum system feature can be integrated.

Our flagship model in the Power Sealer line. Especially designed for dusty, humid or regulated (clean room) production environments. Highly advanced validatable impulse sealer. An 8 mm temperature-, time and force controlled seal. Includes Audion Touch Techware. Optional vacuum system feature can be integrated. Also available in Bag-in-box configuration.

The Power Sealer TC XL and Power Sealer PLUS XL have the largest sealing length of the Audion Power Sealer range. With a sealing length of 2500 mm they can effortlessly provide your largest products with customized packaging or protective covers by means of an 8 mm seal. Available in a temperature controlled model (PSR TC XL) and a validatable model (PSR PLUS XL) with validation on temperature-, time- and seal force controlled sealing. Optional vacuum system feature can be integrated.

Unique steamsealer enabling bags to be sealed without electrical power supply. Instead, it uses pressurized steam to operate. suitable for explosive environments. 8 mm temperature controlled seal. Optional vacuum system feature can be integrated.

Our Power Sealer PLUS XL in use

Let's have a chat

Do you want to know what the Audion Power Sealer XL can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion