Products

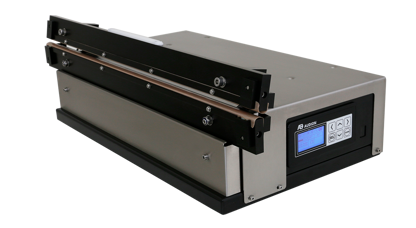

Validatable Power Sealer

Powerful and solid impulse sealer to control critical seal parameters and make consistent 8 mm seals

Interested in our Validatable Power Sealer models?

We are more than willing to support you with your request or run a demo with your packaging

Validatable Power Sealer customized to your needs

Critical sealing parameters, such as sealing force, sealing temperature and sealing time are monitored with the Validatable Power Sealer to ensure end-to-end safety of your products during transport within the supply chain.

The care-free nature of these validatable impulse sealers contributes to an efficient and reliable workflow. The powerful pneumatically driven sealbars provide a reliable validatable 8 mm seal, even during intensive use.

The Power Sealer is fully configurable to make the ultimate fit to your market. Optionally the machines comes with integrated vacuum and gasflush system which can be enriched with several specialized options. Every option is smartly engineered by Audion with one objective: creating the perfect package for your securely protected product, meeting all requirements in your market.

Your Power Sealer advantages:

- Uncompromised product protection for both (long-term) storage and transportation

- Monitored and controlled critical seal parameters (1 recipe)

- Expert in-house (re)-calibration services and replacement parts available from stock

- Data logging available

- Increased ease of work and reduction of product waste

- All our Validatable Power Sealer models are compatible with EN 868-5 and DIN 58953, part 7 norms. Our Val PSR / Val Vac PSR series also fully comply with the ISO 11607-2 and ISO/TS 16775

This makes your machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Reduces the package size + extends the shelf life of your product

Configurable with integrated vacuum and gas flush system enabling MAP (Modified Atmosphere Packaging)

Continuous high seal quality

Sealing temperature, sealing time and seal force are controlled and monitored, ensuring a consistent seal quality, even during higher sealing intensity.

Engineered to maximize your product safety

Select from countless standardized configurable options

Easy-to-use

User-friendly digital control panel (calibratable temperature controller)

Videos

An integrated Vacuum and/or Gas flush system

All Validatable Power Sealers can be configured for ‘sealing only’ or with an integrated vacuum system.

Audion's Vacuum Power Sealers are equipped with a venturi pump generating a powerful vacuum, ideal for operating in a continuous packaging process, reducing production time. The venturi pump is virtually maintenance free (operating without oil). The vacuum system can be combined with gas flush to create modified atmosphere packaging (MAP).

An integrated vacuum system can be used for:

- Volume reduction of the package to save storage and shipment costs

- Applying a modified atmosphere (MAP) to extend the shelf-life of food products

- Prevention of oxidation of, for example, printed circuit boards or other delicate products.

Benefits

The Audion Validatable Power Sealers give you the following benefits

- Integrated Validation:

- Your impulse sealer can be controlled and monitored on critical seal parameters like seal temperature, seal time and seal pressure.

- Powerful Venturi pump:

- All vacuum sealers are constructed with a powerful and practically maintenance free Venturi pump.

- Reliability on every seal:

- Bi-active validatable sealing bars guarantee a strong and reliable seal even for thicker bags.

- Every sealer custom-fit:

- The wide selection of available options ensures the best fit packaging machine for your market.

- Full safety:

- Care-free packaging solution that fully complies with the ISO 11607-2 and ISO/TS 16775 validation requirements.

Options

The following options are available on the Audion VAL PSR

- Clean room solutions:

- In order to meet with the stringent requirements of your cleanroom classification Audion offers several solutions like silicone poor, ESD, external exhaust, various filters etc.

- Vacuum and gasflush system:

- Vacuum and/or MAP packing, even multi-cycle is possible to reduce the volume and safeguard the packed product.

- Nozzle configurations:

- Wide, single, multiple and extended nozzles are available to accommodate your specific packing requirements and to efficiently create the best vacuum/MAP packaging for your products.

- Calibration service:

- Audion has her own certified calibration service to guarantee that your packaging solution is always performing at calibrated values. Take advantage of first-hand factory knowledge and expertise, parts readily available from stock and fast processing to get your machine returned in the best possible state and ready for production resumption.

- IQ / OQ:

- The purpose of the Installation Qualification and Operational Qualification is to establish documented evidence that the packaging equipment is correctly installed, operates according to requirements, and performs safely.

Accessories

The following accessories are available on the Audion VAL PSR

- Industrial Support Frame:

- To optimize sealing height, sealing angle and maximize ergonomic advantages. Various extra support options are available to suit your need.

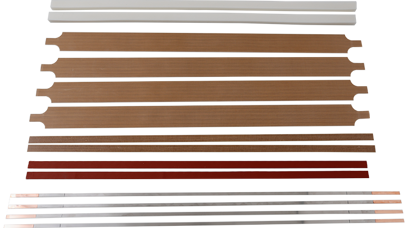

- Set of wearing parts:

- Convenient set for quickly replacing the PTFE, rubber and seal wire to do easy maintenance. To guarantee an optimal sealing result, also after regular use.

Spare parts

Almost all Audion machine parts are readily available from stock, ensuring timely replacements and maintaining high seal quality during your packaging processes.

- Webshop

- Visit our webshop to explore the range of Audion original quality wearing parts.

Specifications

More specifications of the Audion Validatable Power Sealer

- Seal length:

- 520, 720 or 1020 mm

- Seal width:

- 8 mm

- Type of seal:

- Temperature-, time- and force controlled impulse seal

- Validation feature:

- Seal temperature, seal time and seal force (tolerance per 10N) can be controlled.

- Operation:

- Digital control panel, 1 recipe

- Covering:

- Stainless steel

- Pedal operated:

- Yes

- Type of film:

- PE (Polyethylene), Aluminum Laminated Bags

- Required air pressure:

- > 6 Bar

- Thickness of film:

- 2 x 200 micron

- Classification:

- 2014/35/EU Low Voltage Directive; 2006/42/EC Machine Directive; 2014/30/EU EMC-Directive; RoHS 2 2011/65/EU, EN-ISO 11607-2; EN-ISO 12100, EN-ISO 4414, EN-ISO 14118, EN-IEC 60204-1

Explore your options

Customize your Validatable Power Sealer to your unique requirements

Monitor all critical seal parameters

Visualization software to export and investigate the seal data.

Optimize your vacuum process

A powder filter or liquid separator is available to prevent contamination and ultimately protect your product.

Comply with the regulations

Especially designed (cleanroom) solutions are available to guarantee the safety and quality of your products, such as exhaust options or an electrostatic discharge function

Calibration certificate by Audion

Our experienced service engineers apply their in-house expertise to calibrate both your new and operational Power Sealers to safeguard and maintain the highest standard of seal integrity

Discover our Power Sealer line:

This no-nonsense Power Sealer forms the solid basis of the renowned Power Sealer line. The outstanding 5 mm sealing performance is achieved by a pneumatic bi-active and time-controlled impulse sealing system. Optional vacuum system feature can be integrated.

This model is validatable and generates an 8 mm temperature- and time controlled seal. The validation enables that critical seal variables like seal force, seal temperature and seal time are being controlled. Optional vacuum system feature can be integrated.

The Power Sealer TC is a high-performance temperature controlled sealing machine designed for demanding packaging needs in the high-tech and food industries. It features a durable stainless steel housing, touchscreen interface, and powerful bi-active and pneumatic seal bars that ensure consistent, airtight seals. Optional vacuum system feature can be integrated.

The next step in the Power Sealer line is the Plus version. With its unique and most precise system of validation it meets todays' most stringent packaging requirements. 8 mm Temperature- , time- and force controlled seal. Includes Audion Touch Techware. Optional vacuum system feature can be integrated.

Our flagship model in the Power Sealer line. Especially designed for dusty, humid or regulated (clean room) production environments. Highly advanced validatable impulse sealer. An 8 mm temperature-, time and force controlled seal. Includes Audion Touch Techware. Optional vacuum system feature can be integrated. Also available in Bag-in-box configuration.

The Power Sealer TC XL and Power Sealer PLUS XL have the largest sealing length of the Audion Power Sealer range. With a sealing length of 2500 mm they can effortlessly provide your largest products with customized packaging or protective covers by means of an 8 mm seal. Available in a temperature controlled model (PSR TC XL) and a validatable model (PSR PLUS XL) with validation on temperature-, time- and seal force controlled sealing. Optional vacuum system feature can be integrated.

Unique steamsealer enabling bags to be sealed without electrical power supply. Instead, it uses pressurized steam to operate. suitable for explosive environments. 8 mm temperature controlled seal. Optional vacuum system feature can be integrated.

Available spare parts

Related products

Let's have a chat

Do you want to know what the Audion Validatable Power Sealer - VAL PSR can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion

![VAL VAC PSR 520 [1]](/media/vowfxthw/val-vac-psr-520-1.jpg?width=335&height=188&v=1d8486c0c6f05a0)